Alumina PCBs Perform in Thermal Cycling Tests

Alumina PCBs provide a high level of performance in demanding environments. Their superior electrical, thermal and mechanical properties make them ideal for a wide range of applications, from LED lighting to power electronics. They are fabricated using complex procedures and high temperatures, and must undergo rigorous inspection and testing to ensure they meet all the necessary standards. Among the key benefits of alumina PCBs are their good thermal conductivity, dimensional stability and resistance to corrosion. However, there are some challenges associated with these PCBs, including their high cost and long fabrication lead times.

alumina pcb is an excellent choice for high-density circuit boards that require a low profile. Its insulating and dielectric properties help to reduce noise and EMI. Its dimensional stability is also important, as it can withstand high temperatures and mechanical shock. Additionally, alumina has excellent chemical durability and does not corrode in harsh environments.

The material can withstand a wide range of temperatures, from -55 to +300 degrees Celsius. It can also withstand high levels of electric field strength, preventing the occurrence of dielectric breakdown and arcing. Alumina also has good etching and solderability, which makes it an ideal substrate for electronic devices.

How Do Alumina PCBs Perform in Thermal Cycling Tests?

In addition, alumina is not susceptible to moisture absorption like FR-4, which can cause outgassing and vapor pressure stresses under heat. It is an ideal choice for high-density boards that must withstand a high number of thermal cycles.

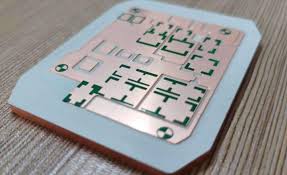

During the manufacturing process, copper is plated directly onto alumina to create conductive tracks and pads. The circuit patterns are etched into the copper layer, which then gets bonded to the alumina substrate with a high-temperature glue. The copper-alumina interface is strong and can withstand temperatures of up to 600degC, which allows for effective heat dissipation.

Alumina PCBs are used in a variety of industrial applications, including aerospace and military electronics, LED lighting and automotive power devices. They are able to operate in demanding environments and provide higher power densities than traditional copper-based PCBs. The high thermal conductivity of alumina allows these circuits to dissipate more heat, increasing the life and reliability of the device. Alumina also offers good mechanical strength and can withstand vibrations. It can be difficult to work with, however, due to its high melting point and the need for specialized assembly techniques.