Circuit Card Assembly Manufacturing

Circuit Card Assembly (CCA) is a central component of most electronic devices. It serves as the backbone for component mounting, signal routing, and power distribution. However, the complexities of CCA can be difficult to unravel without a thorough understanding of what goes into it. This comprehensive guide delves into the essentials of CCA manufacturing, offering key insights and critical know-how.

PCBs are the foundation for modern electronic devices. They are built from a variety of materials including copper, graphite, multilayer ceramic, and FR4 laminate. In order to create a circuit board, it must first be designed using specialized CAD software. Once the design is complete, it must be transferred to a CAM system for production. The next step is to etch the desired patterns on the substrate. Once the circuit board is etched, it can then be soldered and assembled. The final step is testing and ensuring that the circuit board is functional.

circuit card assembly is a complex process that requires a lot of precision and attention to detail. Fortunately, technology has advanced over the years to allow for more efficient and reliable methods of assembly. Some of these new technologies include high density interconnect (HDI) circuit boards and chip-on-board (COB). This allows for more components to be placed on a smaller piece of board while improving the overall reliability of the device.

The Ultimate Guide to Circuit Card Assembly Manufacturing

In addition to a wide range of technological advances, there are other factors that influence the success of circuit card assembly. For example, it is essential that the correct components are used to ensure proper function and efficiency. In addition, the manufacturing process itself must be consistent and reliable. This is why it’s important to work with a turnkey circuit board manufacturer who can handle every aspect of the project.

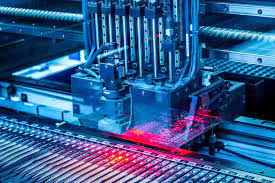

When it comes to the specifics of CCA, there are a few different assembly methods. One is surface mount technology, or SMT, which uses highly specialized machines to place the individual components onto the board. This method is incredibly accurate and fast, making it ideal for larger production runs. Another assembly method is through-hole, which utilizes more traditional components such as soldering wire to attach the parts to the board.

For smaller production runs, hand soldering is the preferred method. This method requires the use of a small amount of solder paste, which is applied to the bare circuit board. It is then covered with a layer of solder mask, which protects the underlying copper from contaminants and makes it easy to see where to apply the individual components. Finally, a thin layer of silkscreen is added to the top of the circuit board. This helps to ensure that the components are placed in the correct locations and prevents them from moving during the soldering process.